Well, you might not know this, but finding the right CNC lathe machine manufacturer isn’t as straightforward as it sounds. When I first started exploring options for my small engineering workshop, I was honestly overwhelmed. There are so many suppliers, each claiming to have the “best” machines, the “most reliable” service, or “unbeatable prices.” It felt like navigating a maze without a map.

What I learned through that experience is that the choice isn’t just about price or specs—it’s about trust, reliability, and understanding your own workflow needs. So if you’re on the hunt for a CNC lathe manufacturer that won’t let you down, here’s a little guide that could save you some headaches.

Table of Contents

Understanding What a CNC Lathe Can Do

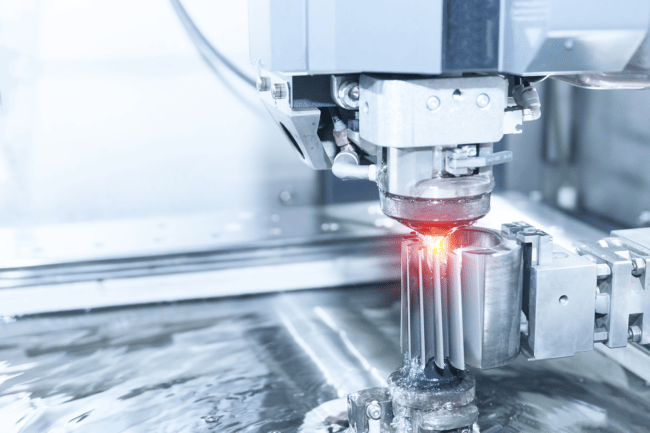

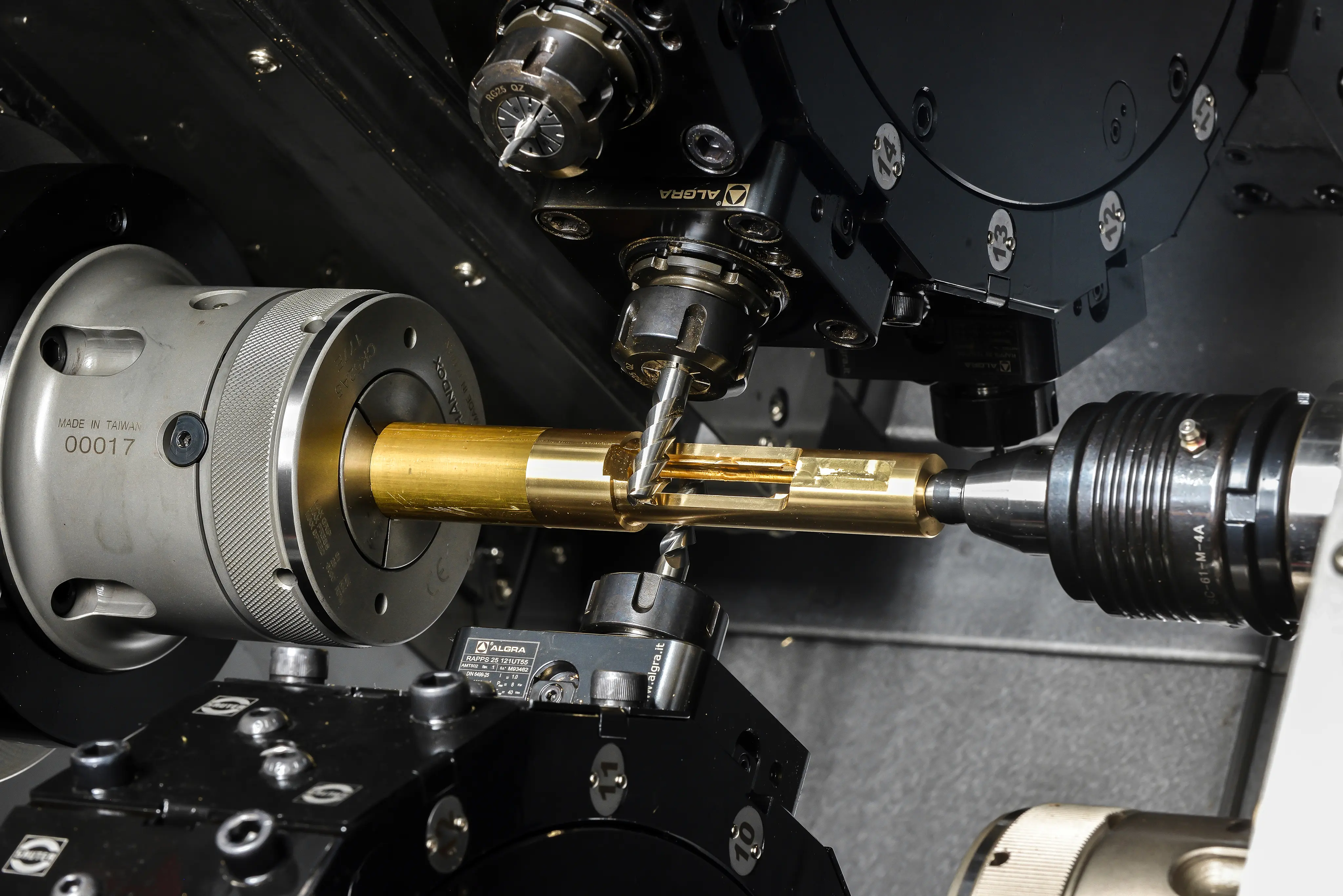

Before you even think about suppliers, it’s worth taking a step back. A CNC lathe isn’t just a fancy tool—it’s essentially the backbone of modern precision machining. These machines allow you to automate cutting, shaping, and drilling processes with astonishing accuracy. Honestly, seeing one in action for the first time blew me away. The way it can replicate intricate designs over and over without fatigue is something even the most skilled human machinist would struggle to match.

Depending on your project needs, you might look for specific features: multi-axis control, high-speed spindles, or even smart monitoring systems that alert you to maintenance issues. These little things can make a huge difference over time.

Why the Manufacturer Matters

Here’s the thing: not all CNC lathe suppliers are created equal. You could buy the most sophisticated machine on paper, but if the manufacturer’s support is lacking or spare parts are slow to arrive, that shiny machine quickly becomes a headache.

I remember reading about someone who invested in a high-end lathe, only to find that replacement parts took weeks to ship internationally. Their production line stalled, and costs skyrocketed. That experience made me realize just how important it is to vet the CNC lathe manufacturer itself, not just the machine.

Look for manufacturers with:

- Proven track records and client testimonials

- Transparent maintenance and warranty policies

- Readily available support teams

- A commitment to innovation and continuous improvement

When I stumbled upon Jsway, I was pleasantly surprised. They’re not just a CNC lathe supplier; they actively work with clients to understand workflow requirements and offer ongoing support. You can check them out here: www.jsway-cnc.com.

Questions to Ask Before Buying

It’s easy to get dazzled by specs and features, but I learned that asking the right questions is crucial. Here are a few I wish I had asked sooner:

-

What is the machine’s tolerance level? Precision matters more than speed in many industries.

- How easy is maintenance and sourcing parts? Downtime kills productivity.

- Is there on-site or remote technical support? You don’t want to be left troubleshooting alone.

- Does the manufacturer offer training? Some suppliers provide tutorials and workshops for staff.

By running through these questions, you not only gauge the machine’s quality but also get a feel for the manufacturer’s customer service ethos.

Real-World Considerations

One thing that surprised me was how much workflow integration matters. You can have the best lathe on the market, but if it doesn’t sync with your existing CNC software or other equipment, you’ll waste hours—or worse, ruin parts. I started mapping out my production process before even looking at machines. That little exercise helped me shortlist manufacturers who offered lathe models compatible with my setup.

Another factor is scalability. If your business grows or diversifies, you want a CNC lathe manufacturer that can grow with you. Some suppliers, like Jsway, offer modular machines or flexible options that adapt to changing demands—something I never thought I’d appreciate until I expanded my operations.

Budgeting Without Compromising Quality

Look, I get it—budget is always a concern. But I learned that skimping on the machine or choosing the cheapest supplier often backfires. You might save a few thousand dollars upfront, but ongoing repairs, downtime, and inefficiencies can quickly outweigh any initial savings.

Instead, focus on value over cost. A reputable CNC lathe manufacturer provides durable machines, robust warranties, and reliable service—these factors pay off in the long run. Honestly, investing in a high-quality machine feels like buying peace of mind.

The Human Factor

Here’s something that often gets overlooked: the human factor. Machines are tools, but the people behind them—engineers, customer service reps, and support teams—make a huge difference. When I worked with a supplier who really cared about my needs, it felt like they were part of the team. They answered questions patiently, guided me through setup, and even followed up months later to ensure everything ran smoothly.

That’s why I often recommend checking out the testimonials and real-world experiences of other clients. It gives you insight into what working with the manufacturer will actually feel like—beyond glossy brochures and technical specifications.

Wrapping It Up

Honestly, choosing a CNC lathe manufacturer is a bit like choosing a business partner. You want someone reliable, responsive, and aligned with your goals. Take the time to research, ask questions, and think beyond specs and price tags.

For anyone starting out or even expanding their workshop, I can’t overstate the importance of picking a supplier who will be there for the long haul. If you’re curious, take a look at www.jsway-cnc.com—their approach to client support and quality is genuinely impressive.

At the end of the day, a CNC lathe isn’t just a machine; it’s an investment in your craft, your team, and your future projects. And when you find the right manufacturer, it can transform the way you work in ways you didn’t even imagine.