Honestly, most people don’t think much about where everyday metal parts come from. You pick up a sleek kitchen appliance, a car component, or even a phone casing, and it just… exists. But if you’ve ever spent time around manufacturing — or even just talked to someone who does — you know there’s a whole world of precision, noise, trial-and-error, and quiet pride behind those parts.

I didn’t grow up dreaming about machine tools. Not even close. But somewhere along the way, while working with brands in industrial and B2B spaces, I started noticing something: the companies that make the machines rarely get the spotlight, yet they quietly shape entire industries. And few machines are as central to modern manufacturing as the CNC lathe.

If you’re looking for a cnc lathe machine manufacturer, a cnc lathe manufacturer, or a reliable cnc lathe supplier, this topic probably isn’t academic for you. It’s personal. It’s about output quality, delivery timelines, and whether the machine on your shop floor becomes a trusted workhorse or a constant headache.

So let’s talk about it — not in a salesy, brochure-heavy way, but like real people who care about making good decisions.

Table of Contents

Why CNC lathes still matter (more than people admit)

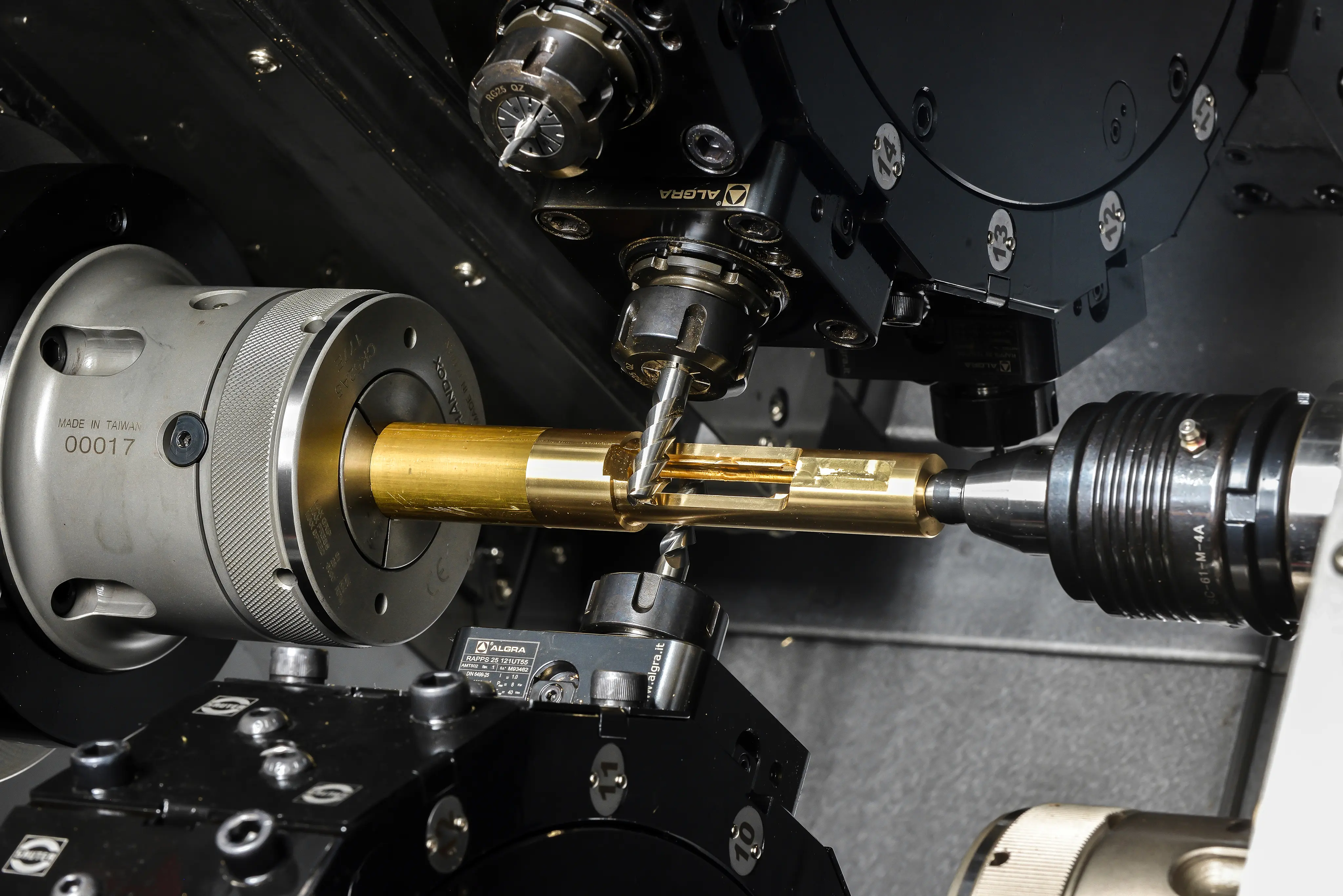

There’s this misconception that manufacturing is all robots and push-button automation now. And sure, automation plays a huge role. But CNC lathes sit right at the heart of that world. They’re the machines shaping metal day in and day out, often running for hours without complaint — if they’re built right.

A CNC lathe doesn’t just spin metal. It defines tolerances. It determines whether parts fit perfectly or cause costly rework. It affects how confident operators feel during a production run. When you zoom out, the lathe becomes less of a machine and more of a backbone.

What surprised me, honestly, is how much difference the manufacturer makes. Two machines can look identical on paper — same specs, same dimensions — yet behave very differently in the real world. That’s where the experience and philosophy of a CNC lathe manufacturer really show up.

What separates a good CNC lathe manufacturer from an average one

This is something I’ve heard repeatedly from shop owners and engineers: it’s not just about speed or accuracy. Those are table stakes now.

A strong cnc lathe manufacturer tends to obsess over details most buyers don’t notice at first. Things like spindle stability after long runs. Thermal control when the shop temperature fluctuates. How intuitive the control panel feels at 2 a.m. during a late shift.

And support — that’s a big one. Because even the best machines need service eventually. When something goes wrong, you don’t want vague email replies or weeks of silence. You want someone who understands your setup and speaks your language.

This is also why many buyers don’t just look for a machine — they look for a long-term cnc lathe supplier. Someone who’s in it with them for years, not just until the invoice is paid.

The human side of machine selection

You might not know this, but a lot of machine-buying decisions are emotional. I’ve sat in meetings where numbers and specs were on the table, yet the final choice came down to trust. To gut feeling.

Does this manufacturer seem like they actually understand my industry? Have they worked with companies my size? Will they still answer the phone when I’m scaling up or dealing with a tricky custom order?

That’s where stories and reputation matter. A cnc lathe machine manufacturer with real-world experience often speaks differently. Less buzzwords. More practical advice. More “Here’s what usually works” and less “Here’s what looks good in a catalog.”

A quiet name that keeps coming up: Jsway

Over time, while researching manufacturers and talking to people across different regions, one name kept popping up in conversations: Jsway.

Not in a flashy, hype-driven way. More like, “Yeah, we’ve been using their machines for a while — they’re solid.” That kind of recommendation carries weight.

Jsway positions itself as a practical, engineering-focused CNC lathe manufacturer. From what I’ve seen and heard, their approach leans toward consistency and adaptability rather than chasing trends. Their machines are used across automotive, aerospace, and general industrial applications — which usually means they’ve been tested in demanding environments.

If you’re curious, their official site — www.jsway-cnc.com— gives a clearer picture of their product range and technical capabilities. It’s not overly dramatic or exaggerated, which, frankly, I appreciate. It feels like a place built for engineers, not marketers.

Why supplier reliability matters more than ever

Here’s the thing: global supply chains are still unpredictable. Lead times shift. Parts get delayed. And when your production schedule depends on a single machine, every delay hurts.

That’s why choosing the right cnc lathe supplier isn’t just about machine quality — it’s about communication, transparency, and logistics. A supplier who’s upfront about timelines and realistic about capabilities can save you a lot of stress.

Some manufacturers promise everything. Others promise what they know they can deliver. The latter group tends to earn loyalty, even if their prices aren’t the lowest on paper.

The balance between innovation and reliability

There’s always a temptation to chase the newest features. Faster speeds. Smarter software. More automation. And innovation matters — don’t get me wrong.

But seasoned buyers often look for balance. They want machines that incorporate modern technology without sacrificing reliability. A CNC lathe that’s too complex can become a bottleneck if operators struggle to use it efficiently.

Manufacturers like Jsway seem to focus on that middle ground — modern enough to stay competitive, stable enough to run daily without drama. And in real manufacturing environments, that stability is gold.

Thinking long-term, not just purchase-day excitement

One shop owner told me something that stuck: “The first week with a new machine is exciting. The next five years are what matter.”

It’s true. Anyone can make a machine that performs well during a demo. The real test is how it behaves after thousands of cycles, routine maintenance, and the occasional operator mistake.

When evaluating a cnc lathe machine manufacturer, it’s worth asking uncomfortable questions. How long do spare parts stay available? How often do control systems get updated? Is training provided, or are you on your own?

The answers to those questions often reveal more than glossy brochures ever could.

Final thoughts: choosing with clarity and confidence

At the end of the day, choosing a CNC lathe isn’t just a technical decision. It’s a business decision, a people decision, and sometimes even a personal one.

You want a machine that shows up every day and does its job. You want a manufacturer that stands behind their work. And you want a supplier relationship that feels like a partnership, not a transaction.

Whether you’re expanding your shop, upgrading older equipment, or entering CNC machining for the first time, taking the time to understand who you’re buying from matters. Brands like Jsway, and others operating with a similar mindset, remind us that manufacturing is still deeply human — built on trust, craftsmanship, and long-term thinking.